| SCAN

Z – INSTRUCTIONS rev. 2 |

|

WHAT

YOU NEED

MAKING

INDICATOR STRIP

SETTING

UP THE SCANNER

SCANNING

USING

SCAN Z

EXTRA FUNCTIONS

WHAT

YOU NEED

To begin scanning there are a few essential items. The first

is a digital camera. Almost any digital camera will do, as long

as it has a tripod mount hole at the base.

The

second is a laser line generator, or laser level. This one is a GMC Redeye Deluxe

Laser Line Generator. I grabbed it from the hardware for around

$60. It also has a standard tripod mount hole. Apparently Lowe's

is the exclusive distributor for GMC products in the US, but I have not seen this item available anywhere other than Australia. It would appear that Craftsmen have this exact same laser with different coloured plastic. Everything else about it seems identical. These are available from Sears. The product is called the Craftsman Laser Trac™ Level with Carrying Case and Laser Enhancing Glasses. (Sears item#00948251000 )

NOTE: A laser pointer will not suffice for this purpose as they only project a small dot. Laser line generators have a lens in them that splits the laser point into a vertical or horizontal line. The thinner and brighter this line is, the better.

The

third item is a rotating platform or turntable of some description. This is a Vogel's 32cm rotating television stand

(TVS 032). It was

$30, and is smooth and very sturdy. I then printed out a thin indicator strip all the way around

the base with marks at regular intervals. I have placed marks

at 15 degrees

(24 segments), 7.5 degrees (48 segments) and 3.75

degrees

(96 segments).

MAKING

INDICATOR STRIP

The indicator strip can end up being very long, so it may need

to be printed in sections, and then joined together. You will

need some sort of illustration application such as Adobe Illustrator,

that will enable you to place lines at accurate increments.

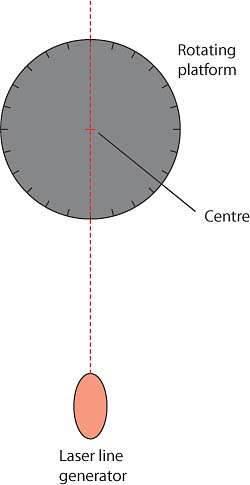

STEP 1. Measure the diameter of the rotating platform.

For those of you who get your radius and diameter mixed up,

the diameter is the distance from edge to edge, slicing right

through the centre of the platform. The platform shown above

has a diameter of 317mm (12.5"). Next we need to work out

the circumference. This is easily calculated with the formula

diameter x pi (3.1415927). For my rotating platform, that would

be 317mm x 3.1415927 = 995.9 mm (39.2").

STEP 2. Armed with the circumference value, now we need

to create our indicator strip with the increment marks. I have

chosen to create my indicator strip with marks at every 3.75

degrees, 7.5 degrees and 15 degrees. This allows me to capture

the object in 24, 48 or 96 segments respectively. The number

of increments you use is entirely up to you. Perhaps you want

to scan very high resolution objects, and would like to be able

to photograph 200 segments, or perhaps you want to scan low

res objects of only 12 segments or less. Just keep in mind that

the demo version of Scan Z is limited to only 12 segments. Work

out how many increments you want, and then divide your circumference

by that figure. For my example, creating marks for 24 increments

would mean drawing a line every 41.5mm (995.9mm ÷ 24

= 41.5mm). Now you can print out the indicator strip, and stick

it to your platform with glue or double-sided tape.

NOTE: If you are a registered user of Scan Z, you can send

me the diameter of your rotating platform, and I will send you

back an eps file with the increments marked out along the circumference.

SETTING

UP THE SCANNER

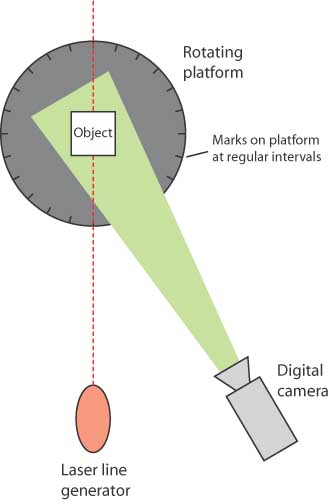

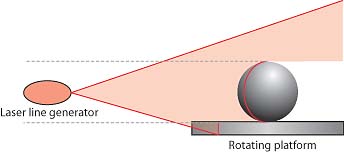

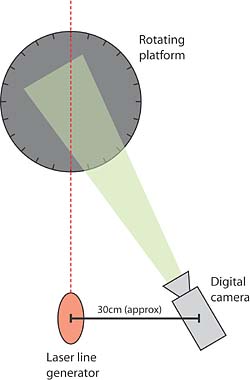

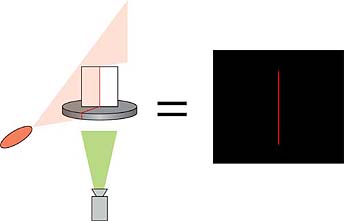

The three items will need to be set up in a triangle as seen

below.

You

can mount the camera and the laser line generator onto a piece

of timber, which can then be mounted onto a tripod. A tripod

isn't entirely necessary, as long as you have a way of securing

the camera and laser in position so that they can't move during

a scan. I have successfully made a scan by simply placing all

three items onto a sturdy table. If your resources are unlimited,

you could place the camera and the laser on their own separate

tripods. The tripod mount screw at the bottom of most cameras

takes a standard 1/4" bolt, which you can purchase in a

range of lengths from any good (even bad) hardware store. If

you should require more information on this process, feel free

to send me an email.

NOTE: Do not swap the position of the laser line generator and the camera. At this time, Scan Z will only function correctly in this configuration.

Next you need to place the rotating platform on a table, approximately

60cm (2') away from the camera and laser. This distance will

vary depending on the size of the subject to be scanned.

Do not have the camera and laser too close to the object. If

you are forced to use a wide-angled setting on your camera,

you can introduce barrel-distortion to your images. This can

affect the shape of the photographed laser line and distort

your object. It is preferable to place the camera further away

from the object, and then zoom-in. This will minimize the barrel-distortion.

You should position the laser so that the line it generates

slices straight through the centre of the rotating platform.

You should be able to gauge this by eye.

The

height of the laser should be at the centre of the object to

be scanned.

The

camera should be positioned on the right-hand side of the laser

line generator. The distance away from the laser will vary depending

on the subject matter. The further away, the greater the scanning

accuracy, but some highly detailed objects will obscure the

laser line if the camera is too far away. In these instances,

you should position the camera a little closer to the laser.

The setup I use has a number of holes drilled in the piece of

mounting timber, allowing me to easily reposition the camera

depending on the subject matter. If you are unsure what distance

to use, 30cm (12") is a good starting point.

The

height of the camera should be positioned so that the object

appears dead-centre of the viewfinder while the camera is completely

flat.

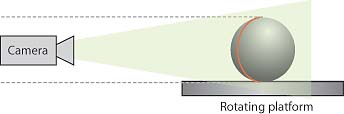

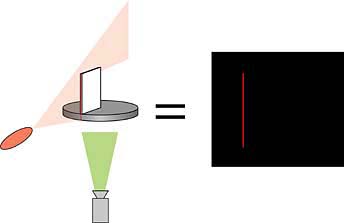

SCANNING

Realistically, when I say scanning, I really mean photographing.

You will be taking a series of photographs of the item to be

scanned from a variety of angles. The photo that you take can

have a significant effect on the end result. You MUST ensure

that the flash is turned off when you photograph. Wherever possible,

you should also try and photograph in very low light. Because

the laser beam is so strong, even if you can see nothing else

in the photograph, the laser line is all that is needed. The

digital camera I use has the ability to change the exposure

time and the aperture, allowing me to shoot very dark photographs,

even in the daytime. This is what you want to try and achieve.

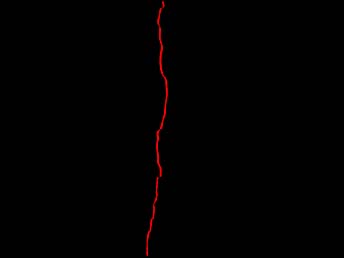

Below is an example of one of my photographs.

This

was shot in near darkness, and will produce a very good result

with the Scan Z line recognition.

STEP

1. Once you have all of your items in position, place the

object to be scanned onto the centre of the rotating platform.

Look through the viewfinder of the camera, and check that the

whole item can be seen. Swing the platform around a bit, and

be sure that the item will be contained in the frame of every

photo.

STEP 2. Now it is necessary to calibrate for the photo shoot.

To do this, you need a calibration item with a known height

and width. I use a piece of Fomecore cut into a rectangle 15cm

wide (6") by 20cm (8") high. I then attach another

piece of Fomecore at a right angle, so that the flat surface

can stand upright. Remove the object to be scanned from the

rotating platform, and temporarily replace it with the calibration

item. Place it in the direct centre of the rotating platform,

so that the laser line will appear as a vertical red line, shooting

right up from the centre of the platform. Take a photo.

STEP

3. Now you need to calibrate a specific distance away from

the centre. My calibration item is 15cm wide, so I place one

end at the very centre of the rotating platform, and then rotate

the platform until the laser is drawing a line right down the

edge of the calibration item. This way the Scan Z software will

now know the exact location of 15cm away from the centre of

the platform. Take a photo.

STEP

4. Return the object to be scanned to the platform, and

make sure it is secure. It must not move for the duration of

the scan. Rotate the platform until the laser line is shining

on your start mark of your rotating platform. Take your first

photo. Rotate the platform to the next mark and take another

photo. Repeat this process until you have rotated the platform

all the way around. Now that the photos are taken, we need to

run them through Scan Z.

USING SCAN Z

STEP 1. Once you have all the photographs on your computer,

create a folder, and place your two calibration photos inside.

Now create a new folder inside this one, and place all of the

photos of your object inside.

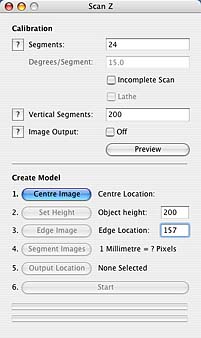

STEP 2. Launch the Scan Z application. You will see two

windows: the main Scan Z interface, and the Status window. To

begin with we will look at the Scan Z interface. You will notice

that the interface is broken into two areas: Calibration and

Create Model.

STEP

3. Enter the number of segment photographs you have taken

into the Segments field at the top of the window.

STEP 4. You will now need to decide what vertical resolution

you are going to use for your model. The figure you enter will

dictate the number of divisions for the full height of the photograph,

not just the subject matter. If your object takes up half of

the height of the image, and you enter a figure of 100, your

model will be split into 50 vertical polygons. If the figure

is too low, you may miss important detail from your scan. If

it is too high, you may end up with unnecessary polygons. You

may need to experiment with this figure to find the optimum

resolution. The demo version of Scan Z is limited to a resolution

of 40.

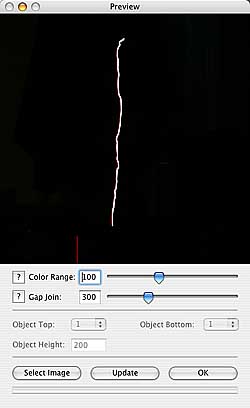

STEP 5. Because your lighting conditions may vary each time

you scan an object, you can calibrate Scan Z to adjust to your

photographs. This can be done interactively by clicking the

Preview button. This will open the Preview window.

Click

the Select Image button and navigate to the folder containing

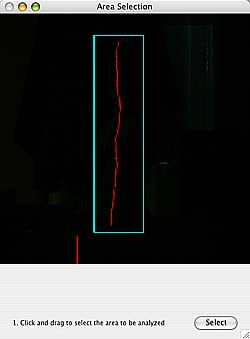

your images. Select a photo from your image sequence. This will open the Area Selection window.

Click and drag around the part of the image that contains the red line. This process is so that Scan Z doesn't need to process any unnecessary data. Click the Select button. You will now see a small yellow square in the window.

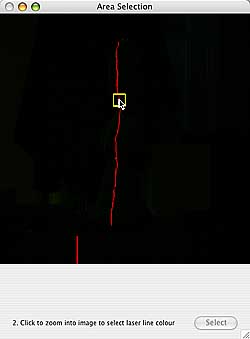

Using the mouse, move the yellow square over a part of the red line, and click the mouse button once. You will see a magnified view of the selected area.

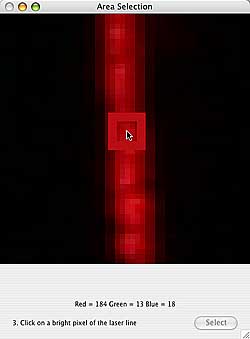

Navigate to a bright part of the laser line, and click the mouse once to select the colour. You will see the RGB colour breakdown at the bottom of the window. If you want to change your colour selection. use the yellow square to select another part of the image, and repeat the colour selection process. Click the Close button to return to the preview window. Scan Z

will now apply the selected settings to the image, and trace

a white line to show where it has detected the laser line. If

the line is incomplete, or displays like an Echidna (porcupine),

you may need to adjust your settings. If the line is not being

recognized, or if there are unwanted breaks in the line, you

will need to increase the Colour Range. The higher the Colour Range, the more of

the image tonal range will be scanned for the line. If your line is

appearing zig-zagged, decrease this value. The Gap Allowance value tells Scan Z what to do with breaks in the laser line.

In some instances, you may scan an object with holes in it,

which will cause the laser line to stop and start. In these

instances, you may want Scan Z to treat these areas as a hole.

Other times, the laser line may have ended up invisible to the

camera in certain areas, but the object still has shape there.

In these instances, you may want Scan Z to simply join the line

where there is a gap. By increasing the Gap Allowance setting, Scan Z will join larger distances. By reducing this

setting, Scan Z will leave these gaps as holes. This value is

based on the gap in the photo in pixels. Each time you make

a change to any of these settings, click the Update button

to see the results.

Once you are happy with the line recognition, click the OK button.

STEP

6. Now we return to the main interface window. Click the

Centre Image button, and select the centre calibration

image you took in Step 2 of the scanning part of the instructions. Select the scanning area and line colour as per the previous step.

STEP 7. Click the Set Height button and the centre

calibration image will be analyzed and then shown in the Preview

window. You will notice that there are now some more calibration

options available. We now have the Object Top, Object

Bottom and Object Height settings. Scan Z should

have automatically detected the top and bottom of the calibration

line, and the Preview window should show a green indicator

at the top and bottom of this line. If the line has become broken

into separate lines, you can use the pop-up menus to select

which start and end points of the calibration image to use as

your height gauges. In most cases, you should not need to change

these settings. Now you need to enter the height of the calibration

object. Select which units you prefer to use from the Units menu. The options are millimetres, metres and inches. I am using millimetres. My calibration item

is 200mm high, so I enter a value of 200. Scan Z can now

calculate the height based on the figure you have entered, and

the length of the line detected from the centre calibration

image. Click the OK button to close the Preview

window and return to the main interface window.

STEP 8. Click the Edge Image button and select

the edge calibration image you took in Step 3 of the scanning

part of the instructions. Select the scanning area and line colour as per steps 5 and 6. Enter the width of the calibration

object into the Edge Location field. My calibration object

is 150mm wide, so I enter a value of 150.

STEP 9. Click the Segment images button and navigate

your way to the folder containing all of your sequence photos. Scan Z will load all of the images into the Area Selection window, so that you can accurately make your selection. Use the slider to scrub through the images in the sequence. Make your area and line colour selection as per steps 5, 6 and 8.

STEP 10. Click the Output Location button and navigate

to where you would like your final obj file to be saved and

name the file however you wish.

STEP 11. Click the Start button to begin the model

construction process. One at a time, Scan Z will analyze the

photos and locate the laser line. The Status window will

show you which image is being scanned, and how long the process

has until completion. You will also see a preview of each image,

and the line recognition as the process takes place. Upon completion,

the preview will quickly animate all the photos that were taken,

followed by a cross section of the objects from top to bottom.

Now the output shape is created. An obj file will be created

at the destination you specified earlier. You can now open this

model into your 3D application.

NOTE: When you open the model, there may be some stray

vertex points. This is just a part of the model creation, and

they can be deleted. In future revisions, Scan Z will no longer

include them in the object file. It may also be necessary to

use the smooth function to help smooth out the points on the

surface.

EXTRA FUNCTIONS

In some instances, you may only need to scan part of an object.

Perhaps you have sculpted a face, and you don't want to scan

the back of the head. You can select the Incomplete Scan

checkbox, and specify how many segments you have, and what the

angle of each segment is. Scan Z will then only analyze the

number of images you have selected, and will only build a partial

model.

The other option is to Lathe an object. If you are scanning

an object that is cylindrical and symmetrical, such as a wine

glass or a beer bottle, there is no need to scan the whole object.

One photograph is all that is necessary. With objects such as

these, take your centre and edge calibration images as normal,

and then take one photo of the object. Select the Incomplete

Scan checkbox, and then select the Lathe checkbox.

You will notice the Segments field changes to '1'. Enter

the degrees per segment into the appropriate field. If you would

like your lathed object to have 100 segments, enter a figure

of 3.6 degrees (360 ÷ 100 = 3.6). Now follow the procedure

for a standard scan, but your object will be constucted from

the geometry of a single photograph only.

|